Compressor - 12V 200psi Continuous Duty - 6lt Tank & Fitment Kit

This system comes with all the following items:

- 12V 200psi AOBCM400 compressor

- 6 litre tank rated at 200psi

- 1.5 meter High Temp Steel Braided Air Hose

- 3 meter Low Temp High Pressure Air Hose

- Manifold Set

- Rubber bush compressor mount

- Full wiring kit

- Installation instructions.

It can be used to fill tires, run Air jacks, pump up mattresses and inflatable boats in good time, run your air lockers, air bags and train horns, even run small Pneumatic air tools all from your 4WD or car.

- 12 Volt DC

- Duty cycle: 100% at 100psi

- Max working pressure: 200 psi

- Amp draw: 23Amps

- Fill a 31/10.5/R15 Tyre from 16 psi to 34 psi in a 1 minuet 22 seconds

PLEASE NOTE: This product is subject to availability, please contact us for more information on lead times.

|

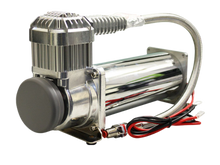

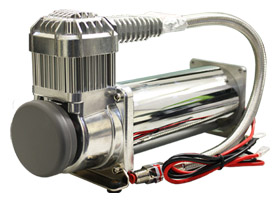

AOBCM400 COMPRESSOR

|

|

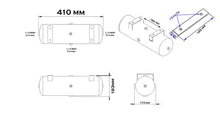

AOBTK206

This is the second smallest tank in our range and has been designed to fit the tightest area. The tank comes including a bottom a drain tap that is used to empty any condensate that is collected during the running cycle along with all the blanking plugs required to fit the full system. |

|

AOBTK206 Dimensions

410mm x 193mm x 173mm. Ensure you have the room to fit this tank. |

|

AOBMB770 MANIFOLD SET

Included with this system are all the air accessories needed for your system in this neat manifold block. Makes for easy installation. |

|

AOBHS104 High Temp Steel Braided Air Hose

|

|

AOB Low Temp High Pressure Air Hose

|

|

WIRING KIT

Everything you need to install and wire this compressor is include in the sale price. Don't get court by buying 12 volt compressors with out the CORRECT wiring kit. By buying it all included you can be assured that you will receive the correct size fuses, relays, switches and wire.

|

|

RUBBER MOUNT The compressor is supplied with rubber vibration pads to protect the compressor from excessive vibration. It is not recommended to mount any 12 volt compressor up side down. Whilst it will still run mounted in this position, the problem is caused by the heat generated by the compressor not escaping correctly and radiating back through the compressor body into the windings. This causing damage to the motor and premature failure of the compressor.

|